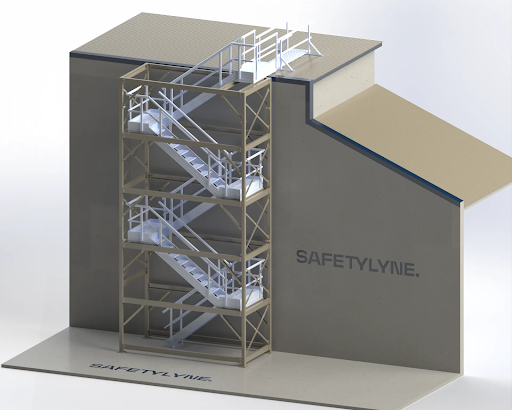

Across Australia’s construction, industrial, and infrastructure sectors, height safety and secure access are non-negotiable. Whether it’s maintaining rooftop equipment, accessing plant decks, or navigating complex multi-level structures, workers rely on stable, compliant, and well-engineered systems to perform their jobs safely. In these environments, stair tower design plays a vital role in creating modern height access systems that enable workers to move efficiently between elevations while maintaining full compliance with national safety standards.

Traditionally, stair towers were developed through manufacturing and fabrication processes using heavy steel or galvanized materials, reliable but often cumbersome to install, maintain, and transport. However, the industry is shifting rapidly toward engineered aluminium solutions. The transition is driven by aluminium’s lightweight strength, corrosion resistance, and adaptability to Australia’s diverse climate and terrain. These systems are not only revolutionizing the way access solutions are designed and installed but also redefining long-term expectations for safety and sustainability.

Understanding Stair Tower Design & Function

A stair tower is a freestanding or integrated structure designed to provide vertical access to elevated work areas such as rooftops, mezzanines, or industrial platforms. These systems are critical in sectors ranging from manufacturing and transport to energy and commercial construction. Their design allows workers to reach elevated zones without the risks associated with ladders, scaffolds, or temporary access structures.

Key Design Considerations

Designing a compliant and safe stair tower involves careful engineering around several parameters:

- Load capacity: Towers must support the combined weight of personnel, tools, and equipment, with additional safety margins built into every calculation.

- Slope and rise: Step angle, tread depth, and riser height are designed for ergonomic movement and stability.

- Guardrails and handrails: Integral to fall protection, these features prevent slips or missteps during ascent or descent.

- Platform spacing and landings: Intermediate platforms enhance safety and comfort over taller installations.

- Modularity: Modern designs use modular components that can be easily assembled, reconfigured, or extended to suit different site conditions.

Compliance plays a central role in stair tower design. In Australia, the key benchmark is AS1657 – Fixed Platforms, Walkways, Stairways, and Ladders, which defines the requirements for safe access systems in workplaces. Ensuring AS1657 compliance guarantees that the structure meets the highest standards for stability, ergonomics, and fall prevention essential for both worker protection and regulatory approval.

Through meticulous design and adherence to engineering standards, stair towers have evolved into reliable, adaptable solutions for permanent and temporary access across Australia’s most demanding worksites.

The Fabrication and Engineering Process

Behind every safe and functional stair tower is a sophisticated engineering and fabrication process. From the initial design stage to the final installation, precision and material integrity are paramount.

1. Design and Engineering

Each project begins with a detailed assessment of the site environment and operational needs. Engineers model structural loads, anchor points, and access pathways using advanced CAD systems. The goal is to produce a tower that integrates seamlessly with existing structures while ensuring total compliance with height safety engineering principles.

2. Fabrication and Welding

Once the design is approved, fabrication begins. Precision cutting, welding, and finishing processes ensure every component meets the project’s safety and durability requirements. Stair tower fabrication often includes modular sections that allow for quick assembly on-site. High-quality welds and surface finishes are vital to prevent fatigue, corrosion, or failure under long-term use.

3. Testing and Certification

Before deployment, the structure undergoes rigorous inspection and testing. Load testing, alignment checks, and non-destructive evaluation methods verify the tower’s integrity. Certification against AS1657 compliance and other relevant codes is then issued — ensuring peace of mind for site owners, contractors, and maintenance teams.

4. The Role of Australian Manufacturing

Australia’s manufacturing sector plays an essential role in the reliability of these systems. Locally produced stair towers reduce lead times, ensure material traceability, and allow direct collaboration between engineers, fabricators, and clients. This Australian made stair tower approach not only guarantees high-quality outcomes but also supports domestic industry standards, innovation, and accountability.

Why Aluminium Is a Better Choice for Stair Towers

One of the most significant advancements in access system engineering is the transition from traditional steel structures to aluminium stair towers. While steel has been the industry’s mainstay for decades, aluminium is emerging as the superior choice for several reasons.

1. Corrosion Resistance

Australia’s climate, ranging from humid coastal environments to arid inland conditions, is notoriously tough on metal structures. Aluminium naturally forms a protective oxide layer that resists rust and corrosion, even without heavy coatings or frequent maintenance. This makes it ideal for roof access safety systems and outdoor installations exposed to the elements.

2. Lightweight Strength

Despite being about one-third the weight of steel, aluminium offers impressive strength-to-weight performance. This characteristic simplifies transport, reduces installation effort, and minimizes structural loads on rooftops and platforms. For facilities where load management is critical, such as data centers, energy plants, and high-rise structures, this is a major advantage.

3. Longevity and Durability

Aluminium’s resilience contributes to extended service life and reduced lifecycle costs. It does not warp, crack, or weaken easily under temperature fluctuations, making it a low-maintenance solution that maintains structural integrity over decades.

4. Ease of Installation

Lighter materials and modular fabrication make aluminium stair towers significantly easier and faster to install. This reduces downtime on site and minimizes the need for heavy equipment during assembly.

5. Sustainability and Energy Efficiency

Aluminium is one of the most recyclable materials on the planet. Its production and reuse cycles are energy-efficient and environmentally friendly, aligning with modern sustainability goals. As construction companies increasingly focus on reducing carbon footprints, aluminium vs steel stairs considerations often favor aluminium for its lower environmental impact.

In summary, aluminium combines safety, practicality, and sustainability making it the material of choice for the next generation of height access systems.

Designed and Made in Australia: A Commitment to Quality

Australia’s engineering and manufacturing landscape is known for its stringent quality standards and regulatory oversight. Locally designed and fabricated stair towers represent a commitment to both safety and reliability.

Local Customization and Compliance

Every site has unique access challenges. By working with Australian engineering teams, project managers can tailor stair towers to meet specific space, load, and safety requirements. This customization ensures full compliance with AS1657 and other regional standards, without compromising on efficiency or durability.

Faster Delivery and Installation

Manufacturing within Australia allows for shorter supply chains, faster delivery times, and easier communication between stakeholders. On-site inspections and client feedback can be incorporated quickly during the design and fabrication stages, improving both quality control and customer satisfaction.

Supporting National Infrastructure and Industry

Australian-made systems are trusted across a wide range of projects from industrial facilities and energy plants to transportation hubs and landmark infrastructure developments. Their proven reliability reinforces Australia’s reputation for engineering excellence and innovation in height safety solutions.

Moreover, choosing Australian-made stair towers supports local jobs, promotes sustainable sourcing, and aligns with national safety expectations, values increasingly prioritized by government and private sector clients alike.

Conclusion: The Future of Safe and Efficient Access Systems

The growing adoption of aluminium stair towers marks a significant step forward in the evolution of height safety systems across Australia. By combining advanced engineering, superior materials, and local expertise, these towers deliver unparalleled strength, safety, and sustainability.

As industries prioritize worker safety, compliance, and environmental responsibility, aluminium’s role will only become more prominent. Its corrosion resistance, modular flexibility, and recyclability make it the clear choice for modern access infrastructure.

Safetylyne exemplifies this forward-thinking approach, engineering stair tower design and fabrication solutions that set new benchmarks in quality and performance, all proudly made in Australia. These innovations protect workers and strengthen Australia’s industrial landscape’s long-term resilience and productivity.