The maritime industry demands precision, reliability, and robust performance in every aspect of vessel operations. From navigation to engine monitoring, shipboard automation, and safety systems, marine environments require technology that can withstand harsh conditions such as saltwater, humidity, vibration, and temperature fluctuations. Marine touch screen displays and monitors have become essential tools for on-board control, providing intuitive interfaces, high-resolution visuals, and rugged durability.

By incorporating industrial touchscreen monitor technology and industrial touch screen display solutions, marine vessels achieve reliable performance, improved operational efficiency, and enhanced safety for crews and passengers.

Why Marine Touch Screen Displays Are Essential

Marine touch screen displays are specially designed for the unique challenges of maritime environments. Unlike standard consumer monitors, these displays are engineered to withstand exposure to saltwater, moisture, dust, and continuous vibration. They provide critical operational interfaces for navigation, engine monitoring, communication systems, and onboard automation.

Key benefits include:

- Durability: Designed to operate reliably under harsh marine conditions.

- High-Definition Clarity: Clear visuals ensure accurate monitoring of instruments and systems.

- Touchscreen Interactivity: Enables operators to interact directly with marine control software and monitoring systems.

- Integration with Industrial Systems: Compatible with industrial touchscreen monitor and industrial touch screen display technology for seamless operation.

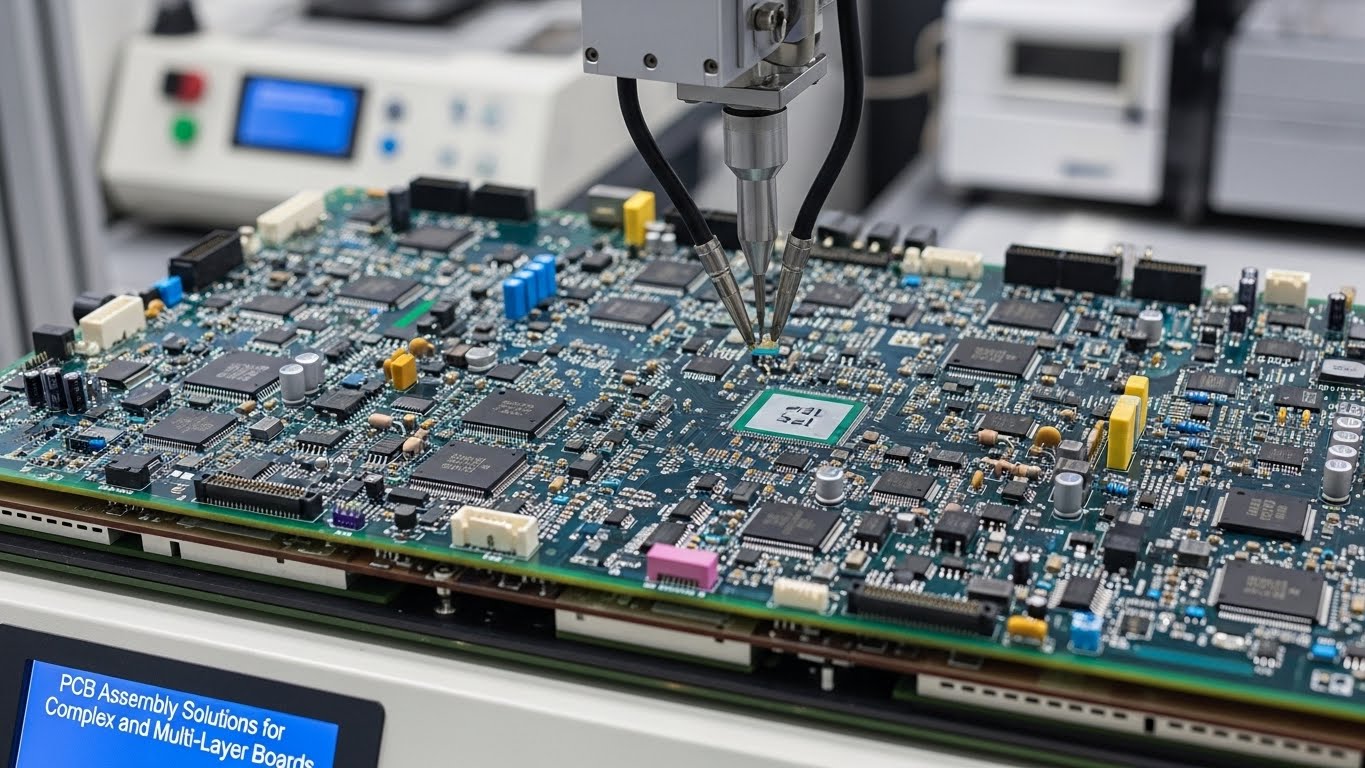

Key Features of Marine Touch Screen Displays

Marine touch screen monitors share many characteristics with industrial-grade display technology, ensuring they can perform in extreme maritime conditions:

1. Rugged and Waterproof Design

Marine displays are built with IP-rated enclosures (commonly IP65 or higher) to prevent damage from water, dust, and debris. Corrosion-resistant materials ensure long-term reliability in the presence of saltwater and humid conditions.

2. High-Definition and Anti-Glare Displays

Clear visuals are essential for navigation and monitoring critical systems. Marine touch screens feature high-resolution displays with anti-glare coatings, allowing operators to view real-time data in bright sunlight or low-light conditions.

3. Responsive Touchscreen Technology

Integrated industrial touch screen display technology allows for intuitive operation, supporting multi-touch gestures and operation with gloves or in wet environments. This capability reduces human error and enhances operational efficiency.

4. Vibration and Shock Resistance

Marine environments often involve constant vibration from engines and waves. Marine touch screen displays are designed with robust housings and shock-absorbing components to maintain consistent performance under these challenging conditions.

5. Wide Operating Temperature Range

Marine displays are engineered to operate across a broad temperature range, ensuring reliability whether on hot, sunny decks or cold offshore waters. An industrial touchscreen monitor integrated with a colorimeter combines precise color measurement capabilities with intuitive touch control, making it ideal for quality control in industries like manufacturing, printing, coatings, and electronics.

Such devices feature a high-contrast touchscreen for real-time display of color data (e.g., Lab*, RGB values) while integrating colorimetric sensors to capture and analyze surface colors, ensuring consistency across production batches. The touch interface simplifies operation—users can directly input color standards, adjust measurement parameters, or compare sample data with benchmarks on-screen, streamlining workflows in quality inspection stations or production lines.

Built with industrial-grade durability (e.g., IP65 protection, wide temperature resistance), these hybrid systems withstand harsh factory environments, bridging the gap between visual monitoring and accurate color analysis for enhanced quality assurance.

Applications of Marine Touch Screen Displays

Marine touch screen displays and monitors are versatile tools used across a wide range of maritime operations:

1. Navigation and Bridge Control

Marine touch screens provide intuitive control for navigation systems, radar, GPS, and autopilot functions. Clear, high-resolution displays allow captains and officers to monitor courses, track positions, and make precise adjustments in real time.

2. Engine and Machinery Monitoring

Industrial-grade touch screens, such as industrial touchscreen monitors, enable crews to monitor engines, fuel systems, and critical onboard machinery. Real-time feedback ensures timely maintenance, efficient fuel usage, and safe operation of mechanical systems.

3. Offshore and Commercial Vessels

Marine touch screens are widely used on commercial vessels and offshore platforms to control automated equipment, track inventory, and monitor safety systems. Rugged displays ensure reliable performance even in extreme offshore environments.

4. Recreational and Passenger Vessels

Yachts, ferries, and cruise ships rely on marine touch screens for entertainment systems, navigation, and operational control. The integration of industrial touch screen display technology ensures intuitive operation for both crew and passengers.

5. Research and Survey Vessels

Vessels conducting oceanographic surveys, marine research, or scientific missions use rugged touch screens for data acquisition, instrument control, and real-time monitoring. High-definition displays allow scientists and operators to track measurements with precision.

Advantages of Marine Touch Screen Displays

- Reliability in Harsh Conditions: Designed to operate in saltwater, humidity, vibration, and temperature extremes.

- Enhanced Operational Efficiency: Touchscreen interfaces simplify complex system controls and reduce human error.

- High-Definition Visualization: Clear, sharp displays improve situational awareness and decision-making.

- Durable Construction: IP-rated enclosures and corrosion-resistant materials extend the lifespan of marine displays.

- Integration with Industrial Technology: Industrial touchscreen monitor and industrial touch screen display technologies ensure compatibility with existing marine automation systems.

Choosing the Right Marine Touch Screen Display

Selecting the appropriate marine touch screen display requires careful consideration of operational requirements:

- Display Size and Resolution: Ensure the screen is large enough for critical data visualization.

- Touchscreen Technology: Choose resistive or capacitive touch based on glove usage, wet conditions, and multi-touch needs.

- Environmental Ratings: Confirm IP rating, corrosion resistance, and shock/vibration tolerance.

- Connectivity Options: Verify compatibility with onboard systems, sensors, and control networks.

- Mounting and Integration: Ensure flexible mounting options for bridge panels, control consoles, or deck installations.

By considering these factors, marine operators can select displays that enhance control, safety, and operational efficiency.

The Role of Industrial Display Technology in Marine Systems

Industrial touchscreen monitors and industrial touch screen displays provide the foundation for reliable marine touch screen solutions. These industrial-grade components ensure:

- Long-term durability in harsh environments.

- Accurate and responsive touch operation.

- High-definition visuals for real-time monitoring.

- Compatibility with complex automation systems and software.

By leveraging industrial technology, marine displays offer both reliability and performance for demanding maritime operations.

GDCOMPT Marine Anti-Glare High-Brightness Touch screen display

GDCOMPT Marine Anti-Glare High-Brightness Tablet PC is a display technology specifically designed for marine environments. In recent years, it has gained widespread attention and application in the shipping industry. It not only solves the reflection problem of display devices under the complex marine environment but also greatly improves the crew’s visual experience and work efficiency during navigation.

During ship navigation, traditional displays often produce strong reflections due to the influence of multiple light sources such as direct sunlight and sea wave reflection, which seriously affects the crew’s visual judgment and operations. The anti-glare matte display can effectively address this issue, allowing the crew to clearly view the on-screen content under various light conditions.

Key Specifications

- Body Material: Aluminum alloy + sheet metal structure design

- Waterproof Rating: IP65 waterproof rating for the front panel

- Screen Brightness: 1000 cd

- Touch Method: 10-point capacitive touch (AG/AR optical bonding customizable)

- Motherboard Solution: Self-developed industrial-grade wide-temperature motherboard (i3/i5/i7 options)

- Installation Methods: Supports embedded, desktop, and wall-mounted installation

Product Features

- Equipped with dual 2.5G network ports, DC 9-36V wide-voltage power supply, and 4K output display

- Runs Windows Embedded system, featuring strong anti-interference ability and corrosion resistance

- Reserved expandable interfaces with complete power supply and data transmission functions

Conclusion

Marine touch screen displays and monitors are critical tools for reliable on-board control. By integrating industrial touchscreen monitor and industrial touch screen display technology, vessels achieve high-resolution visuals, intuitive operation, and robust performance in harsh marine environments.

From navigation and engine monitoring to offshore and recreational applications, these displays ensure operational efficiency, enhance safety, and provide long-term reliability. Investing in rugged, high-quality marine touch screen solutions is essential for modern maritime operations, enabling vessels to operate safely and efficiently under all conditions.

Whether for commercial ships, offshore platforms, research vessels, or yachts, marine touch screen displays are a cornerstone of advanced, smart marine technology.