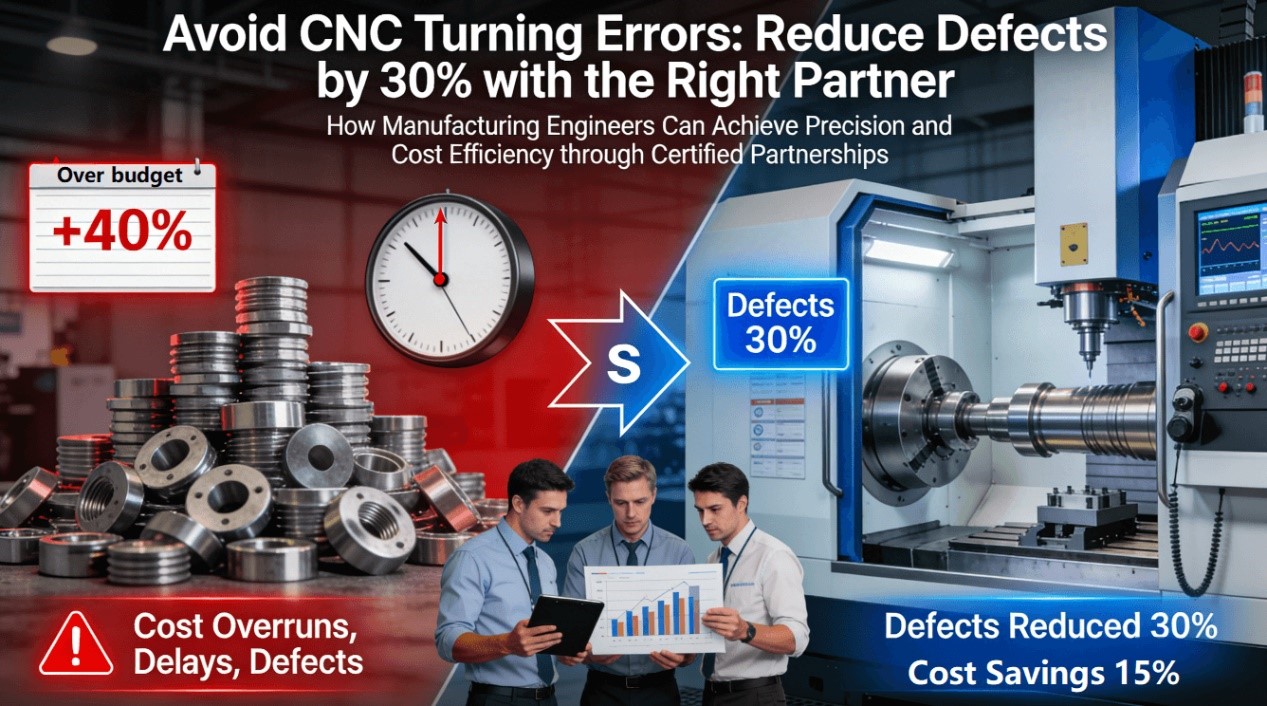

The manufacturing industry is universally dealing with increasing problems associated with resource wastage and cost challenges. The conventional machining techniques are often accompanied by tendencies associated with material wastage and a degree of imprecision. The major problem is associated with a bigger degree of imprecision during conventional CNC machining, and thus there is a challenging balance that needs to be made in precision CNC milling between productivity and sustainability.

Ultimately resulting in a major degree of intensity associated with environmental expenses and losses associated with economic gains considering machines in use today. This paper is intended to analyze that eased problem associated with invention and implementation of precision CNC milling technology solutions within the industry today.

What is Precision CNC Milling, and Why is it a Cornerstone of Modern Manufacturing?

Precision CNC milling implies a refined and advanced form of CNC machining that deals with directing milling machines using computer-controlled systems to remove material from a solid block with incredible accuracy, sometimes as close to ±0.005mm. The following technology manufacturing is fundamental to producing high-quality, complex components.

The Technological Framework and Global Recognition

The dependability of precision CNC milling is an advanced technological basis, while the quality meets international standards and makes it indispensable for a number of critical industries.

- Core Technical Components

Process consistency is underpinned by closed-loop control systems… ensuring the tool path adheres meticulously to the digital design model, which is critical for achieving unparalleled repeatability across production batches.

- The Imperative for Rigorous Standards

The relevance of such precision has been reiterated by world bodies. For example, National Institute of Standards & Technology (NIST) has named precision measurement and process control among the foundations of smart manufacturing. The strict criteria that have to be observed in precision CNC milling form the very basis of developing precision tech industries like the aerospace and healthcare industries.

Advantages over Conventional Machining Processes

When measured against conventional machining processes, there has been a great improvement in efficiency and sustainable manufacturing practices in precision milling. Precision milling is a machining process used to produce parts by removing material through a rotating tool bit widely used in precise machining applications such as CNC milling machines. Outsourcing a professional Precision CNC Milling service allows a company to take full benefit of such a revolutionary improvement.

How to Achieve Sustainable Manufacturing Practices Through Precision CNC Milling?

The integration of greener manufacturing processes into the production core is absolutely essential. Precision CNC machining services play a crucial role in making environmentally conscious and economically successful CNC milling processes a reality for manufacturers.

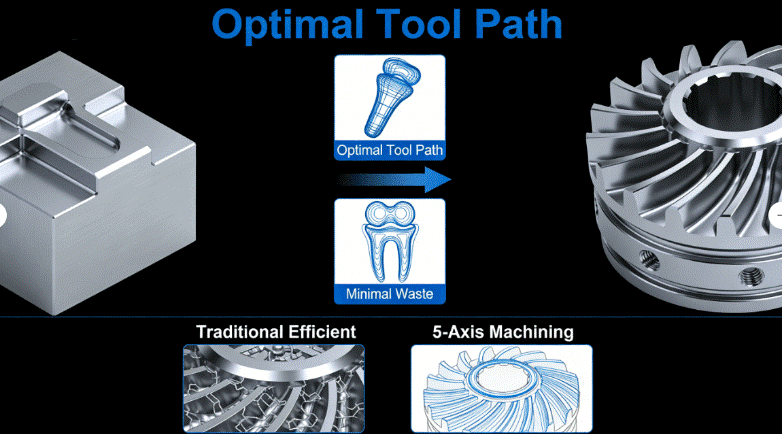

One of the main advantages is that there is a significant amount of material waste reduced. The cutting-edge software used to optimize tool paths ensures that unnecessary material cutting is minimized by pointing to material wastage at its root causes. There have been cases recorded to prove that material wastage by up to 35% has been reduced. Such an optimized material usage not only saves material but also saves money.

Additionally, more precise CNC mills are fitted with energy-saving components such as servo motors and intelligent idle functions. Optimal machining processes ensure the completion of components within a shorter time, hence decreasing total energy use and carbon emissions. Conformity to international standards, such as ISO 14001, regarding environment management systems, indicates alignment to sustainable production processes.

The cumulative impact of these optimizations is a reduction in long-term operational expenditures. Lower production of waste means lower costs of material, while better energy use means lower costs of utilities. Precise and reliable production means lower production of scraps and therefore lowers the costs associated with reworks, which translates to better efficiency of the supply chain.

What Innovative Applications Can be Found in Precision CNC Milling in Rapid Prototyping?

In the competitive area of product development, the application of rapid prototyping is very important in terms of reducing development time and time-to-market. Precision CNC milling introduces new CNC milling applications in prototype development, which provide advantages over conventional applications.

Rapid Iteration of Complex Designs

This technology facilitates rapid design validation of designs by allowing engineers to make functional prototypes from the same material used in the actual product, such as certain aluminum alloys and high-strength plastics. This makes it possible to perform realistic simulations involving mechanics and thereby considerably reduce the time required for the design iteration process. Further, five-axis machining has the capability of producing parts with complex shapes and deeper cavities.

Innovation Driving Industry in High-Stakes Sectors

The use of precision milling in prototyping is especially crucial in industries such as medical and aerospace. The technology is applied in making custom surgical guides or prototypes in medical fields and also in making light structural components for aerodynamic testing in aerospace technology industries. The custom CNC milling services are essential in supporting such high-end activities.

Seamlessness with Digital Design Trends

The combination of Digital Models and Physical Prototyping is enhanced by this technology.

- Enabling Digital Twins

The precise milling prototype provides a high-fidelity prototype to serve as an analogue to what constitutes the product’s digital twin to assure that it is accurate.

- Connecting Design and Manufacturing

Such smooth conversion from a CAD design to a quality custom machined parts helps in better coordination between design and manufacturing teams by successfully implanting Design for Manufacturability.

How Do High-Precision CNC Mills Enhance Reliability in Custom Parts Production?

In the context of clients seeking custom machined components, reliability stands as a key consideration. Advanced high precision CNC mill technology raises this level of reliability with its sophisticated machine as well as quality assurance processes.

The complexity of these machines is also basic for such technology. 5-axis CNC milling machines, for example, offer the advantage of carrying out complex pieces in one operation therefore reducing mistakes resulting from re-fixturing and job orientations from different machines. Such machines also offer better cutting tool angles and therefore better surface finish and tool life.

Besides mechanics, another very important area is intelligent process control. Modern mills are connected with sensors that are monitoring on-line such parameters as force of cut, vibration, and temperature. This makes it possible to perform self-compensations that guarantee the process stability. This adaptability corresponds with the goal of smart manufacturing that is propagated by such bodies as NIST and pertains to the guarantee of quality in the process.

In the end, it is the reliability that is institutionalized by systematic certifications. Production environments with a rigorous standard set by AS9100D in aerospace create traceable and auditable quality management systems right from supply chain management to inspection. Sharing a partnership with a certified vendor means that clients get not only a product but a guarantee for a chain of supply to support the requirements for engineering design trends in the contemporary world.

How Will Future Engineering Design Trends Shape CNC Milling Processes?

The trends in engineering design are inextricably linked with the future of CNC milling technology and are helping to shape technology manufacturing in the coming years. The impact of Artificial Intelligence and the Internet of Things will play an intricate role in this domain. The use of AI will ensure optimal cutting path planning and allow dynamic adjustments in machining, thus reducing wastage and increasing efficiencies at all times. The IoT sensors will enable machine tools to function as intelligence nodes in a network and improve OEE substantially at all times.

At the same time, the need for sustainability, especially the notion of a circular economy, will remain a macro forcing function for process improvements. Coming CNC milling operations will reflect more concerns for recyclable materials and, hence, better disassembling and recycling methodologies for when the part’s life ends. Energy and coolant consumption will become more intelligent and environmental-friendly.

The above trends also firmly stand on a well-established ground. As commented in reports by Society of Manufacturing Engineers (SME) about future scenarios in the manufacturing domain, digitalization, automation, and sustainability collectively form a focal point in the coming era of manufacturing. By embracing digitalization and other technology drivers in future engineering designs in a responsive manner by manufacturers, they could reap opportunities of catapulting agility in a low-cost manner and in a sustainable form.

Conclusion

In short, precision CNC milling offers a solution that incorporates superior cost-effectiveness with environmental benefits attributed to unparalleled accuracy and sustainable practice. It’s a key technology for responding to today’s challenges and is at the very heart of building the agile, reliable, future-ready supply chains needed for competitiveness in today’s manufacturing.

If one is looking for personalized, high-reliability machining options for a certain project, one should at least find a relevant service to provide an instant quote with regard to the detailed specifications of the design in question.

Author Bio

The author is an expert in the manufacturing industry with more than a decade of experience focused on advanced materials and precision machining.The article was created in collaboration with technical assistance from the JS Precision team.

FAQs

Q1: What materials can precision CNC milling handle?

A: Indications are that the technology can manufacture a wide range of materials-from a series of metals, such as aluminum, stainless steel, and titanium, to engineering plastics, for example, PEEK and Nylon. Ensure high accuracy with customized tools and parameters among different materials and therefore could apply in aerospace and medical areas. Material selection has to be made in accordance with design requirements.

Q2: How is the cost of a precision CNC machining service determined?

A: Cost is based on the part complexity, material selected, and production quantity. Detailed CAD drawings are always preferred to give an instant accurate quote. Design for optimization of machining may save as much as 20% of the cost.

Q3: What are the advantages of precision milling in rapid prototyping?

A: Key benefits include high accuracy and material authenticity. It enables functional testing with end-use materials, rapid iteration of designs, and the manufacture of complex geometries with superior surface quality, reducing development cycles.

Q4: How does CNC milling implement the consequences of sustainable manufacturing practices?

A: Implementation occurs through the following: 1. Material optimization through smart tool paths for maximum utilization. 2. Energy efficiency by use of high-efficiency components. 3. Process control according to the standards like ISO 14001 for proper waste management and cooling agents.

Q5: What can be expected in future developments in CNC milling technology?

A: Innovations will focus on smart manufacturing and sustainability. AI will enable adaptive machining and predictive maintenance, while IoT will enhance interconnectivity. Trends also point toward better integration with the circular economy principles, such as lightweighting and sustainable material processing.